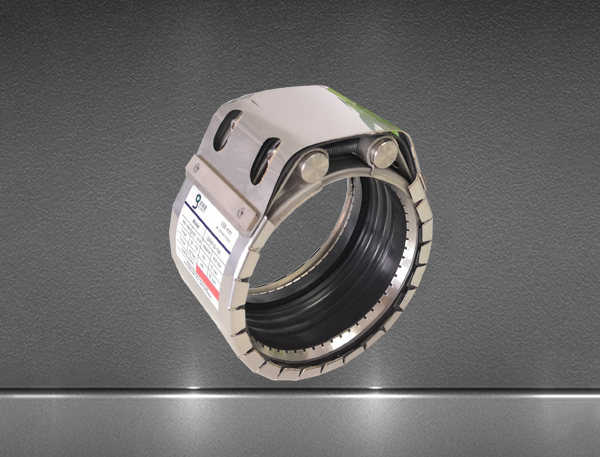

Cúpláil dóiteáin

Comhcheanglaíonn an Grip-GF le dearadh feidhmiúil leis na teicneolaíochtaí is déanaí. The GRIP-GF is based on the proven coupling technology, which has been developed for the shipbuilding industry, also is successfully used for tunneling, fire hose applications etc. In the event of a fire, GRIP-GF coupling protectively enclosing the coupling. Le linn an phróisis seo, coinníonn an cúpláil a chumas oibriúcháin iomlán gan aon damáiste.

Oiriúnach do phíopaí OD φ26.9-φ273mm

Oiriúnach d'ábhar píopaí: cruach charbóin, cruach dhosmálta, copar, cunifer, gre, agus ábhar eile

Paraiméadair Theicniúla Grip-GF

Roghnú Ábhar Grip-GF

| Comhpháirteanna ábhartha | V1 | V2 | V3 | V4 | V5 | V6 |

| Cas | AISI 304 | AISI 316L | AISI 316TI | AISI 316L | AISI 316TI | |

| Bolg | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Barra | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Fáinne ancaire | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 | |

| Cuir isteach stiall (roghnach) | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 |

Ábhar gasket rubair

| Ábhar séala | Na meán | Fadteocht |

| EPDM | Gach caighdeán uiscí, fuíolluisce, aer, solaid agus táirgí ceimiceacha | -30 ℃ suas le+120 ℃ |

| NBR | Uisce, gás, ola, breosla agus hidreacanbóin eile | -30 ℃ upto+120 ℃ |

| MVQ | Leacht ardteochta, ocsaigin, ózón, uisce agus mar sin de | -70 ℃ suas le+260 ℃ |

| FPM/FKM | Ózón, ocsaigin, aigéid, gás, ola agus breosla (ach amháin le stiall a chur isteach) | 95 ℃ Suas le+300 ℃ |

Is ionann an Grip-GF agus cúpláin phíopaí meicniúla cosanta tine ard slándála.

An buntáiste a bhaineann le cúpláil de chineál cruthúnas dóiteáin

1. Ní bheidh aon deatach tiubh agus boladh tar éis dó rubar a dhó nuair a bheidh sé tine, ag tachtadh.

Ní hamháin go gcoinníonn tú cúpláil agus píobán go maith, déan pearsanra a chosaint ó dheannach deataigh rubair agus boladh.

Iarratas:

Tionscail tógála long

Tollánaithe

Píblínte Hose Dóiteáin

Forbairt innill